We produce several kinds of resin bonded grinding wheels, starting from the popular ones and ending on wheels for special applications.

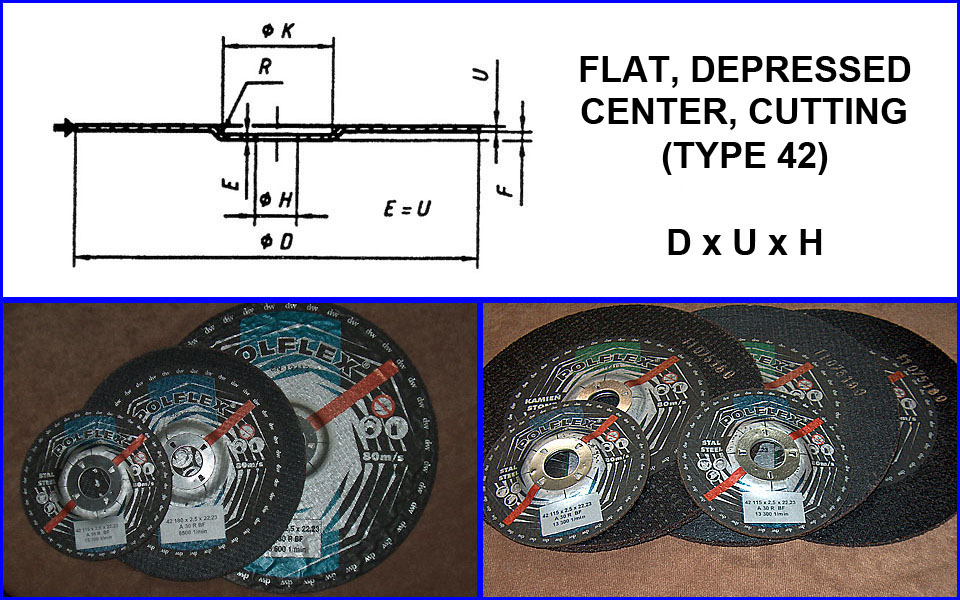

1. GRINDING AND CUT-OFF WHEELS POLFLEX ® REINFORCED with glass fiber fabric (resin bond BF) designed to operate with a maximum peripheral speed of 80 m/s, which, depending on size and use, are the equipment of hand angle or stationary grinders.

They have various applications, e.g.:

-for precise hand cutting of metal thin sheet and profiles (wheels with a thickness of 0.8 mm to 2 mm, fi 50 – 230),

– for ceramic plates hand cutting (wheels fi 115 and 125 mm, hole 22,23 mm, thickness 1 mm)

– for hand cutting and grinding: inox steels, alloy steels and alloys, carbon steel, concrete and stone, cast iron and aluminum alloys (thickness: for cutting 0,7 – 4 mm, for grinding 4 – 10 mm; fi 50 – 400 mm)

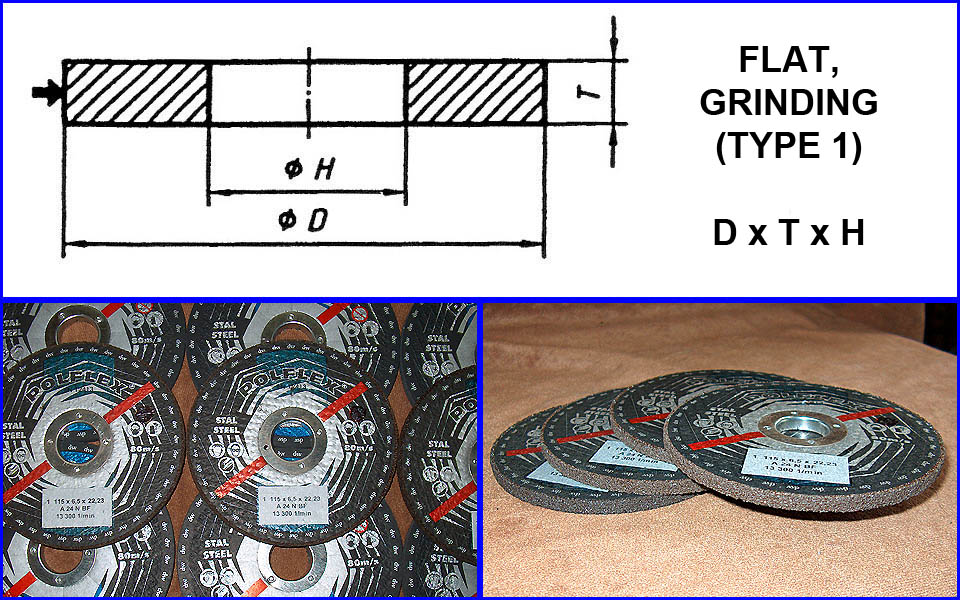

2. POLFLEX ® GRINDING AND SHARPENING WHEELS, depending on the destination subdivided into:

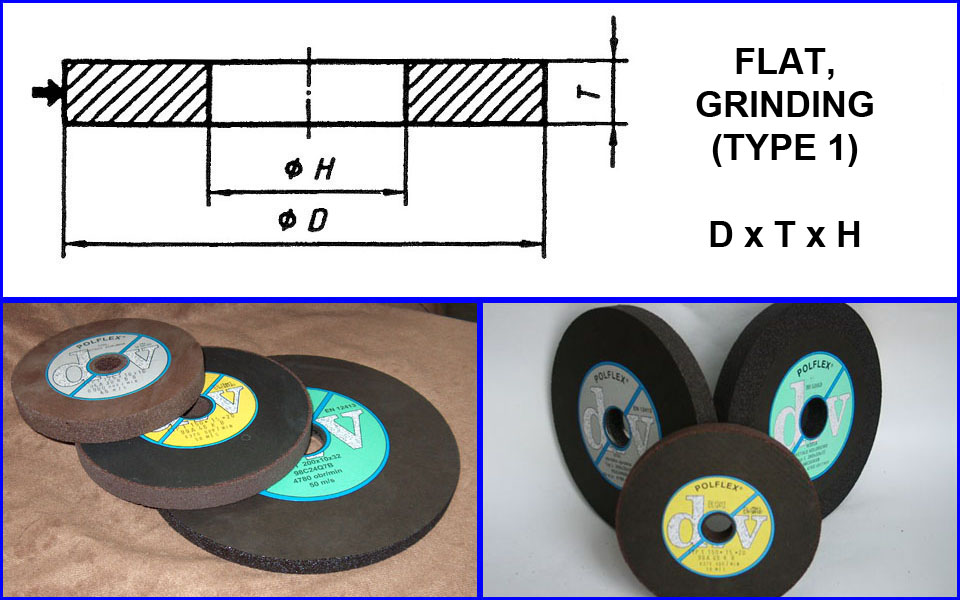

– grinding flat wheels with resin bond (B), type 1, for grinding and sharpening using a hand, table or pedestal grinders, with the maximum peripheral speed of 50 m/s,

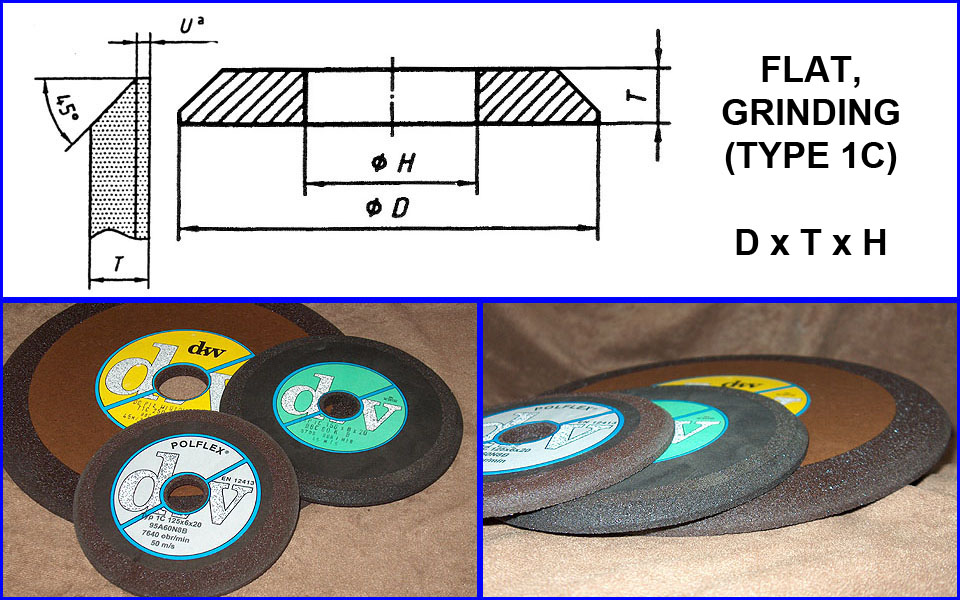

– grinding flat wheels with resin bond (B), types 1 and 1C, for sharpening sawmill saws: band, frame, circular and other blades, with a speed up to 50 m/s using specialized sharpeners,

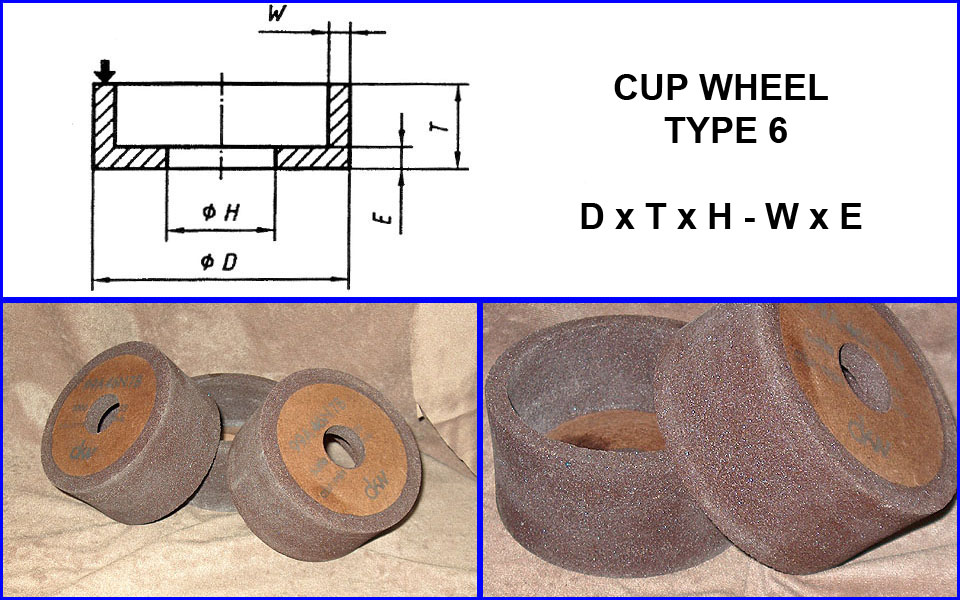

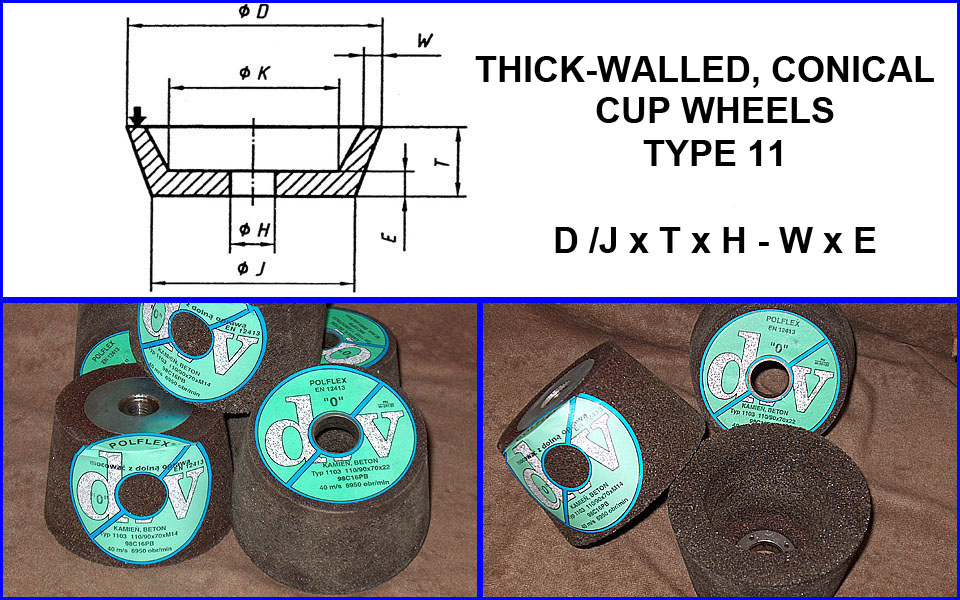

– cup wheels with resin bond (B), straight type 6 and conical type 11, for tool sharpening and grinding of surfaces with the peripheral speed up to 40 m/s,

– thick-walled cup wheels, straight and conical, types 6 and 11, to grind the planes of different materials (metals or concrete) with hand angle grinders with the peripheral speed up to 50 m/s.

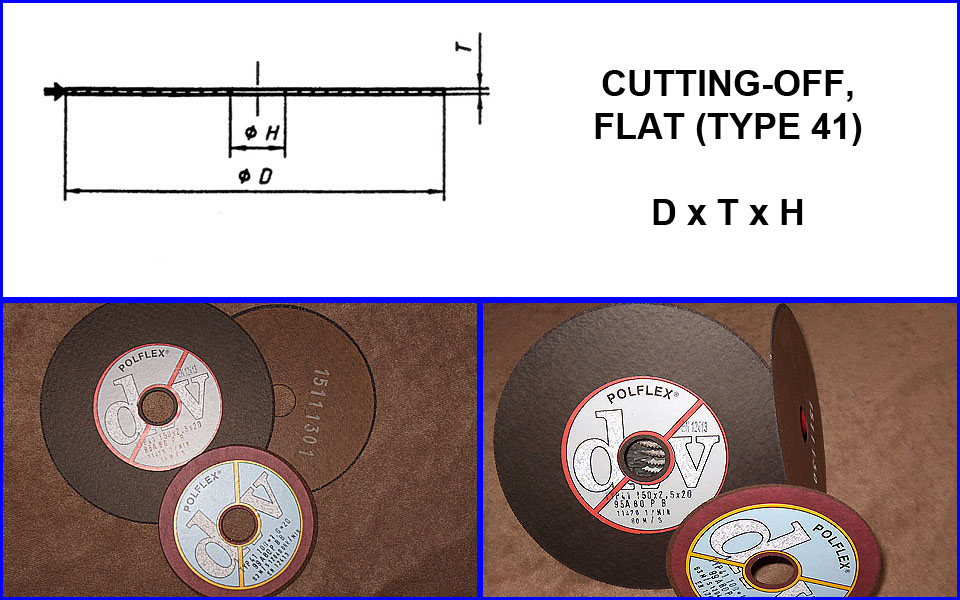

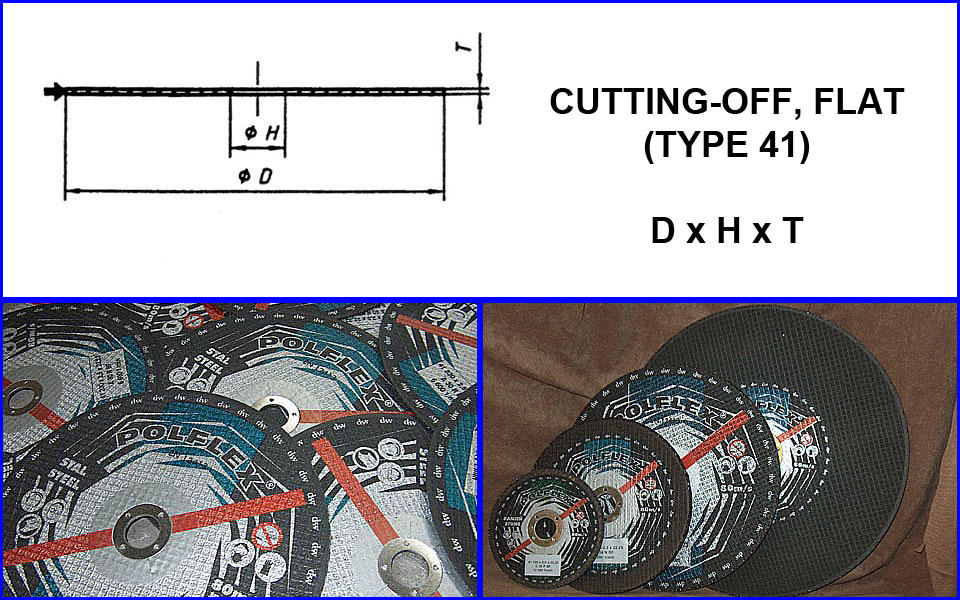

3. CUT-OFF NON-REINFORCED POLFLEX ® FLAT WHEELS (type 41) resin bond (B), for slitting and cutting with precise equipment, including a special version, for cutting metallographic specimens, with a maximum peripheral speed of 63 m/s. They are made with various thicknesses with a step of 0.1 mm.